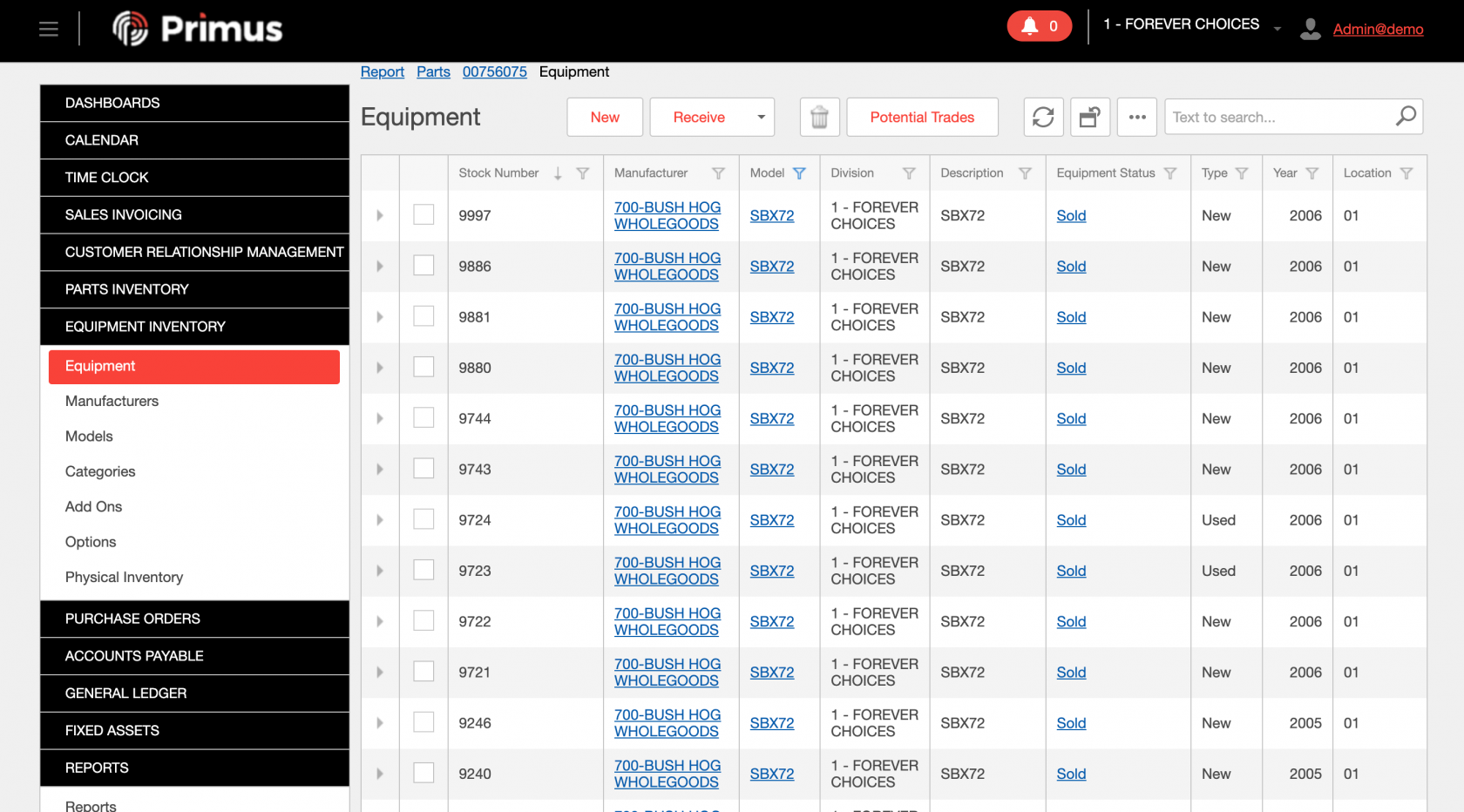

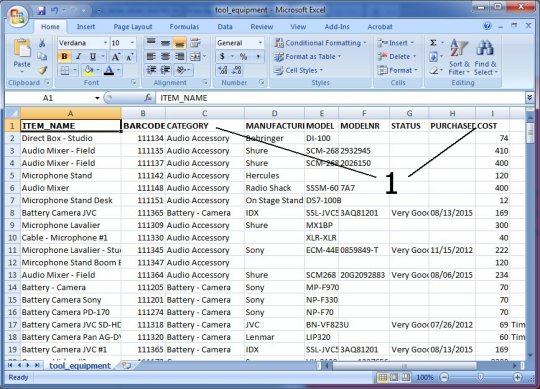

The important thing is that you collect and curate as much of the stock and sales data as possible. but these can usually be obtained by a third party. Other datasets that may play into a forecasting model would be things like weather, holidays, event dates, etc. If your business is affected by seasonal trends, you should collect at least a couple years worth of data. when was each product being promoted (e.g.how many of each product were sold per day/week.what products were in stock each day/week.To implement a forecasting model, you should ideally have historic data regarding Phases of the project 1) DataĪs with any machine learning project, the first step is to collect, interpret, and analyze data.

Nonetheless, it’s worth analyzing the frequency by which products run out of stock and attempting to estimate the financial loss of such occurrences. It’s even less clear how much customer value is lost since understocking drives customers away from a business. Estimating the financial losses from understocking can be difficult since it’s not clear how much product would have been sold if the product were available. Similarly, understaffing a restaurant on a busy day can result in long wait times and poor service, which would also result in loss of customers. Losing a customer can cost hundreds if not thousands of dollars. Understocking milk in a grocery store is likely to drive customers to a competitor. Understocking items is potentially a more severe issue. These financial losses are harder to measure, but depending on the size of the business and quality of the existing inventory demand forecasting model, losses can be tens or hundreds of thousands of dollars annually. For example a clothing store that overstocks on winter coats will 1) reduce limited store space that could have been used to sell winter boots and 2) potentially result in having to sell the coats at a discount or loss come Spring to make space available for new items. Other retail companies face a different issue with overstocking. If a forecasting model can reduce the discarded items by 10%, from 500 items discarded per day to 450 items discarded per day, this would result in an annual savings of $54,750 per year (assuming the model does not increase the number of understocked items). Or equivalently $547,500 discarded per year. X 10 items per product off-shelved per day If just 5% of the outflowing items are discarded, this is a loss of On a typical day you restock the shelves with ten of each product since items are both 1) being sold and 2) being discarded.

Each store sells 100 perishable products with an average unit cost of $3. For example, consider a grocery chain operating ten stores. In the case of grocery stores, overstocked perishable items result in a direct loss since expired perishable items must be discarded. There are two ways such a model can add value: 1) By reducing the amount of overstocked items and 2) By increasing the amount of understocked items. It’s worth discussing the value add of accurately forecasting inventory demand. In this article, I’ll outline a scientific approach for inventory demand forecasting using Machine Learning.

Numerous businesses face different flavors of the same basic problem, yet many of them use outdated or downright naive methods to tackle it (like spreadsheet guided, stock-boy adjusted guessing). Purchase too few and you’ll run out of stock. Purchase too many and you’ll end up discarding valuable product. The classic example is a grocery store that needs to forecast demand for perishable items. The problem of Inventory Demand Forecasting is extremely simple to understand, yet challenging to solve optimize.

0 kommentar(er)

0 kommentar(er)